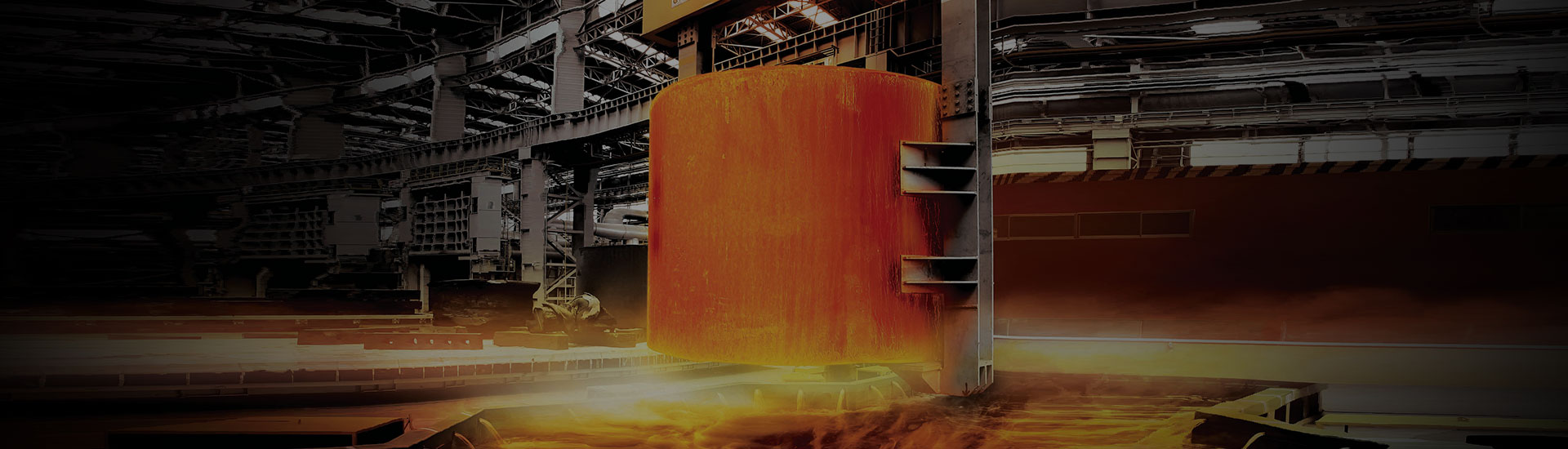

Open Die Forging

SeAH Besteel supplies various open-die forging products. These are used as core part materials for shipbuilding and heavy industry. It leads the market for ultra-large forgings. We base this on our based on its know-how and technology in manufacturing special steel. Which has led the Korean material sector.

01

Production of ultra-large forgings on a 13,000-tonne press

Manufacture and supply core parts for shipbuilding, petrochemicals, power generation, heavy industry, and other industries

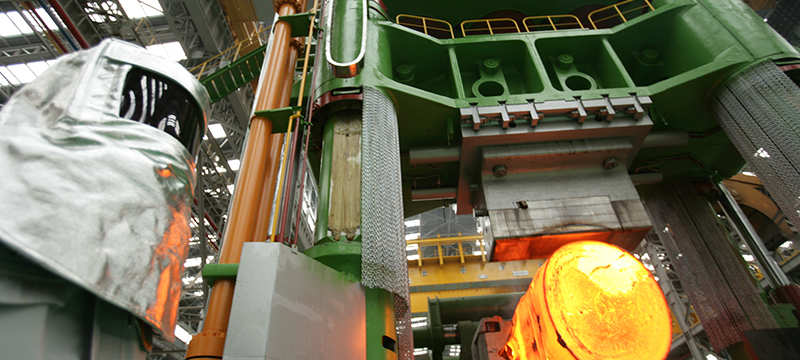

02

Maximizing customer value through integrated production lines

Internalize the entire process, from material to forging, machining, and assembly, to ensure quality stability, and reliability

Main products

-

Shell

ㆍDiameter : Max. 6,800mm

ㆍLength : Max. 5,000mm

ㆍWeight : Max. 250ton

-

Ring

ㆍDiameter : Max. 6,800mm

ㆍLength : Max. 5,000mm

ㆍWeight : Max. 200ton

-

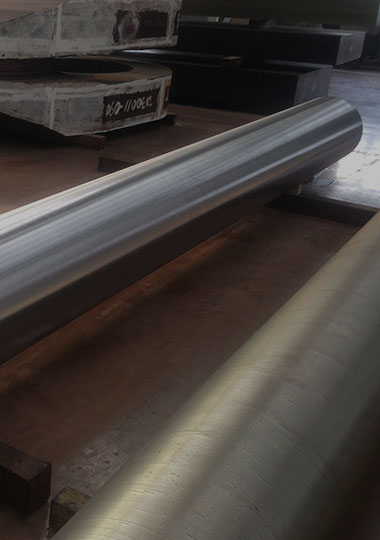

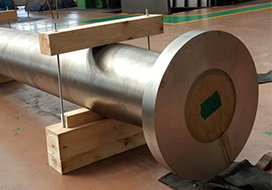

Shaft

ㆍType : Flange, R/Bar

ㆍDiameter : Max. 3,000mm

ㆍLength : Max. 21,000mm

ㆍWeight : Max. 250ton

-

Hollow Bar

ㆍDiameter : Max. 2,500mm

ㆍLength : Max. 12,000mm

ㆍWeight : Max. 150ton

-

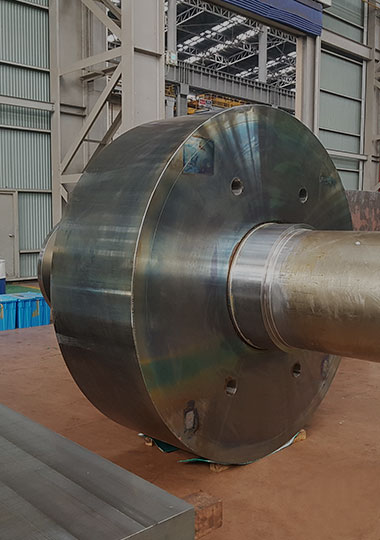

Roll

ㆍDiameter : Max. 3,500mm

ㆍLength : Max. 16,000mm

ㆍWeight : Max. 250ton

-

Disc

ㆍDiameter : Max. 6,800mm

ㆍThickness : Min. 200T

ㆍWeight : Max. 250ton

-

Block

ㆍDiameter : Max. 5,000mm

ㆍThickness : Min. 200T

ㆍWeight : Max. 250ton

-

Mold Steel

ㆍWidth : Max. 5,000W (Width)

ㆍThickness : Min. 200T ~ Max. 1,500T

ㆍWeight : Max. 150ton

-

Ship Engine

ㆍDiameter : Max. K108MC (Man Type)

ㆍThickness : Max. RTA96C (Wartsila Type)

ㆍWeight : Max. 60ton/ea

-

Crank Throw

ㆍA unit part that consists of a ship's crankshaft

ㆍComplete the crankshaft by shrink-fitting several crank throws

ㆍShrink-fitted with journals and then connected with bearings and connecting rods

-

Intermediate Shaft

ㆍA shaft that connects the ship's crankshaft and propeller shaft to transmit power

-

Main Journal

ㆍA part that consists of a ship's crankshaft

ㆍShrink-fitted to crank throws and then connected crank throws to each other

ㆍSupported on the engine's internal bearing

-

Propeller Shaft

ㆍConnect the intermediate shaft to the propeller in the ship

ㆍA part that finally transmits the power generated by the engine to the propeller

-

Rudder Stock

ㆍA shaft connected to a rudder that adjusts the direction of travel of a ship

ㆍCab adjustments are transmitted through the transmission gear to the rudder stock to adjust the direction of the ship

-

Shaft Flange

ㆍA part that consists of a ship's crankshaft

ㆍSupported by the engine's internal bearing after shrink-fitting to the crank throw

-

Thrust Shaft

ㆍA part that consists of a ship's crankshaft

ㆍAssemble it with the intermediate shaft to transmit power to the propeller

ㆍAssemble with a flywheel after shrink-fitting it to the crank throw to store power

-

Roll

ㆍTo squeeze material by rotational motion (for rolling)

-

Industrial Shaft

ㆍAn industrial part that acts as a power transmission

-

Tyre Ring

ㆍA support part for rotating heavy structures in cement plants and other industrial sites

-

Round Bar

ㆍA long industrial base material in a round shape

-

Square Bar, Plate

ㆍA long industrial base material in a rectangular shape

-

Mold Steel

ㆍMold material for injection of various plastics, such as automobiles and home appliances

-

Hydro. Shaft

ㆍA rotating shaft that receives waterfall energy for hydroelectric power generation and rotates to generate electricity

-

Rotor Shaft

ㆍA material for thermal and nuclear power generation, a rotating shaft that receives energy and rotates to generate electricity

-

Shell

ㆍA cylindrical part that consists of a nuclear reactor, heat exchanger, or steam generator

-

Skirt Ring

ㆍA part that connects the head and shell of a nuclear reactor (reactor pressure vessel)

-

Transition Shell

ㆍA cone-shaped shell between a large and small shell in a steam generator in a chemical plant or nuclear power plant

-

Channel Head

ㆍA lid part that connects the tubes in a heat exchanger

Demand industries

Specifications for packing

Wooden packing1 (Part)

Protect the main part of the product with wood and support it with skids

Wooden packing2 (Front)

Protect the front of the product with wood and support it with skids

Vinyl Packing

Place the product on a steel frame, compress it, and wrap it in plastic

Wooden box

Place the product in a wooden crate

Steel Packing

Wrap the front of the product with steel sheets and place it on a steel structure to fully protect it

Skid Packing

Secure with only wood and fully threaded bolts for safe transport (rough machined products)