AUTOMOTIVE

SeAH Besteel has been supplying materials for automotive core parts for a long time and is actively expanding its cooperation with global automotive companies. They recognize our in recognition of its world-class technology and excellent quality.

Special steel

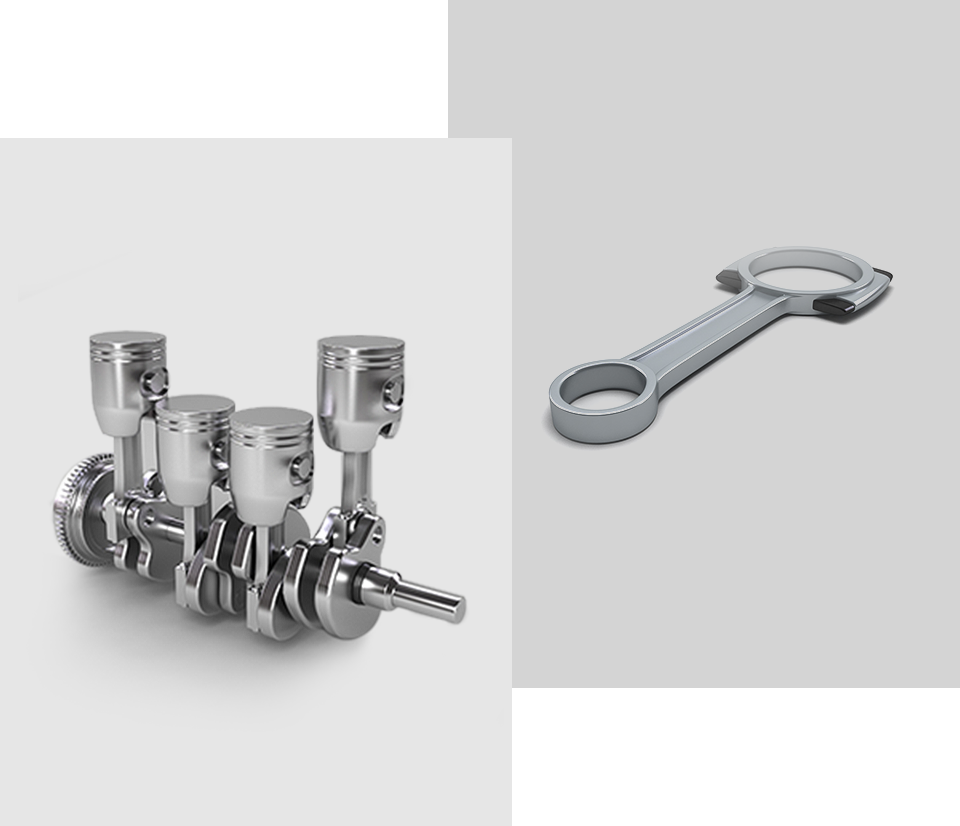

Engine Material

Special steel characteristics : Weight lightening, extended durability life, and better cutting performance

Technical development : Alloy design considers the high strength, toughness, and workability of the material for the crankshaft

Cost savings by skipping QT heat treatment on non-heat-treated steel.

High strengthening and improved cutting performance of materials for connecting rods

Production of steel grades : Medium carbon Cr-Mo, medium carbon Mn-V, high carbon Mn-V, low carbon high strength bainite, 45K grade medium carbon non-heat-treated steels

Parts application : Crank Shaft, Connecting Rod

Special steel

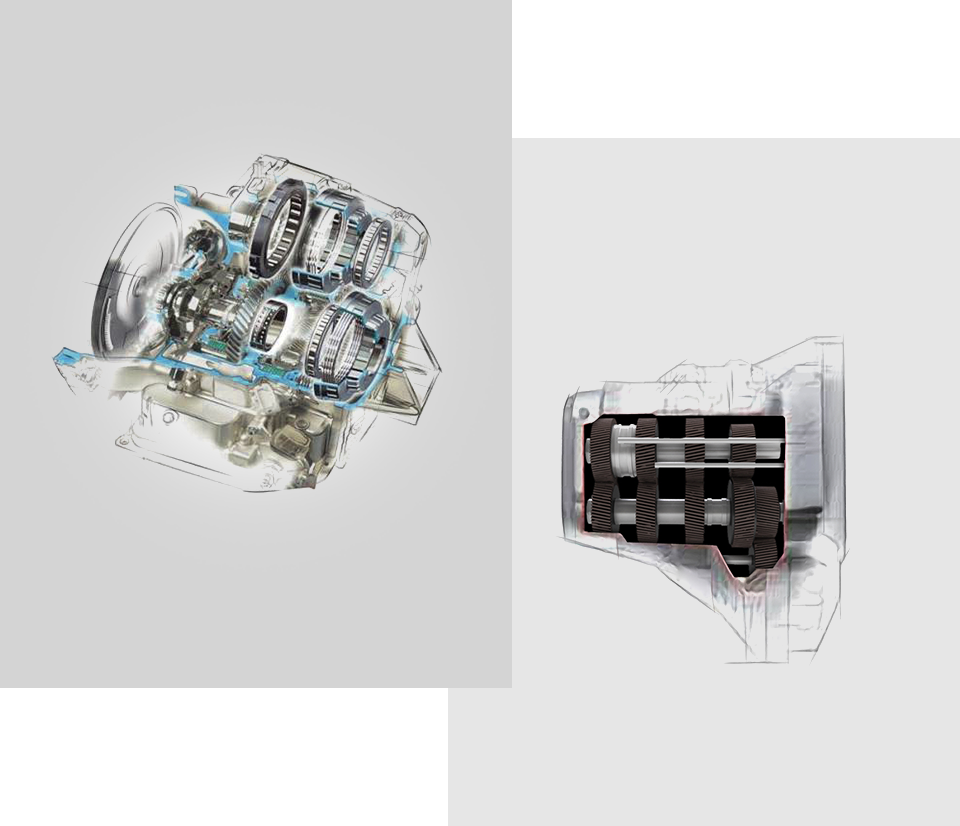

Transmission Material

Special steel characteristics : Weight lightening, extended durability life, and reduced thermal deformation

Technical development : High-frequency heat treatment + ultra-fine grain steel to improve part durability and weight

Production of steel grades : Cr, Cr-Mo, Si-Cr-Mo-Nb, Cr-B-Nb, high-strength ultra-soft steels for gears, high-temperature vacuum carburizing steels

Parts application : Transmission, Gear, Shaft etc.

Special steel

Chassis Material

Special steel characteristics : Weight lightening, extended durability life

Technical development : 3 High-frequency heat treatment + ultra-fine grain steel to improve part durability and weight

Production of steel grades : High carbon Mn-Cr, medium carbon B, high carbon, high carbon Cr, and low carbon carburizing bearing steels

Parts application : CV-Joint and other suspension assemblies

Special steel

Spring Steel

Special steel characteristics : high elasticity, high fatigue strength, and high hot formability

Technical development : addition of alloying elements to improve hardenability and toughness; optimisation of continuous casting and rolling conditions to reduce segregation; optimisation of rolling conditions to minimise decarburization

Production of steel grades : SUP9D, SUP11D etc.

Parts application : Shock Absorber, Stabilizer bar